The University of Liverpool’s Stephenson Institute is part of one of the successful research projects to receive funding to enhance the ‘manufacturability’ of graphene, one of the thinnest, strongest and most conductive materials known.

The consortium between the Universities of Liverpool and Manchester has been awarded a five year, £1.9m grant from the EPSRC, to explore the potential use of graphene within supercapacitors and batteries for energy storage applications.

Graphene has the potential to deliver lucrative technological breakthroughs in areas ranging from electronics to energy generation and telecommunications.

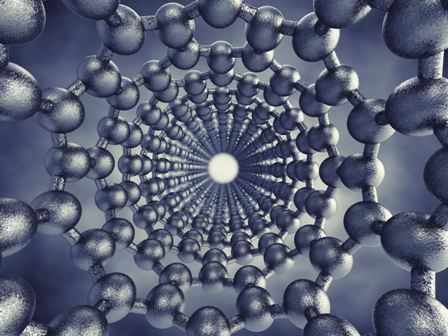

The so-called “super-material” is an atom-thick sheet of carbon molecules, arranged in a honeycomb lattice. It has unmatched electronic and physical properties – it can conduct electricity a million times faster than copper and is more transparent to visible light than any other known conductor. It is also stronger and more stretchable than other conductors.

Research at Liverpool will be led by Dr Hardwick from the Department of Chemistry, and will focus on integrating graphene into batteries to improve their working life and power delivery.

Amongst the numerous applications predicted for this material, exploitation in electrochemical energy storage with supercapacitors or batteries ranks as one of the most prominent.

Dr Hardwick, explained: “The phenomenal growth in use of personal electronic devices and the uncertainty and intermittency of renewable supplies in parts of the world that are off-grid, has driven interest and development of electrochemical (battery and supercapacitor based) energy storage.

However, there are many challenges ahead; we are still some way off the routine incorporation of graphene within battery and supercapacitor electrodes, as either composites for immobilisation or conductivity, or as primary electrode materials. Incorporating graphene into these energy storage devices is problematic as it is generally of poor quality and variable dimensions, and often only minimal effort is made to control the architecture of the graphene in the resultant device. “