A new multi million pound robotic platform that will transform the process of testing and formulating new chemicals has been launched by the Materials Innovation Factory.

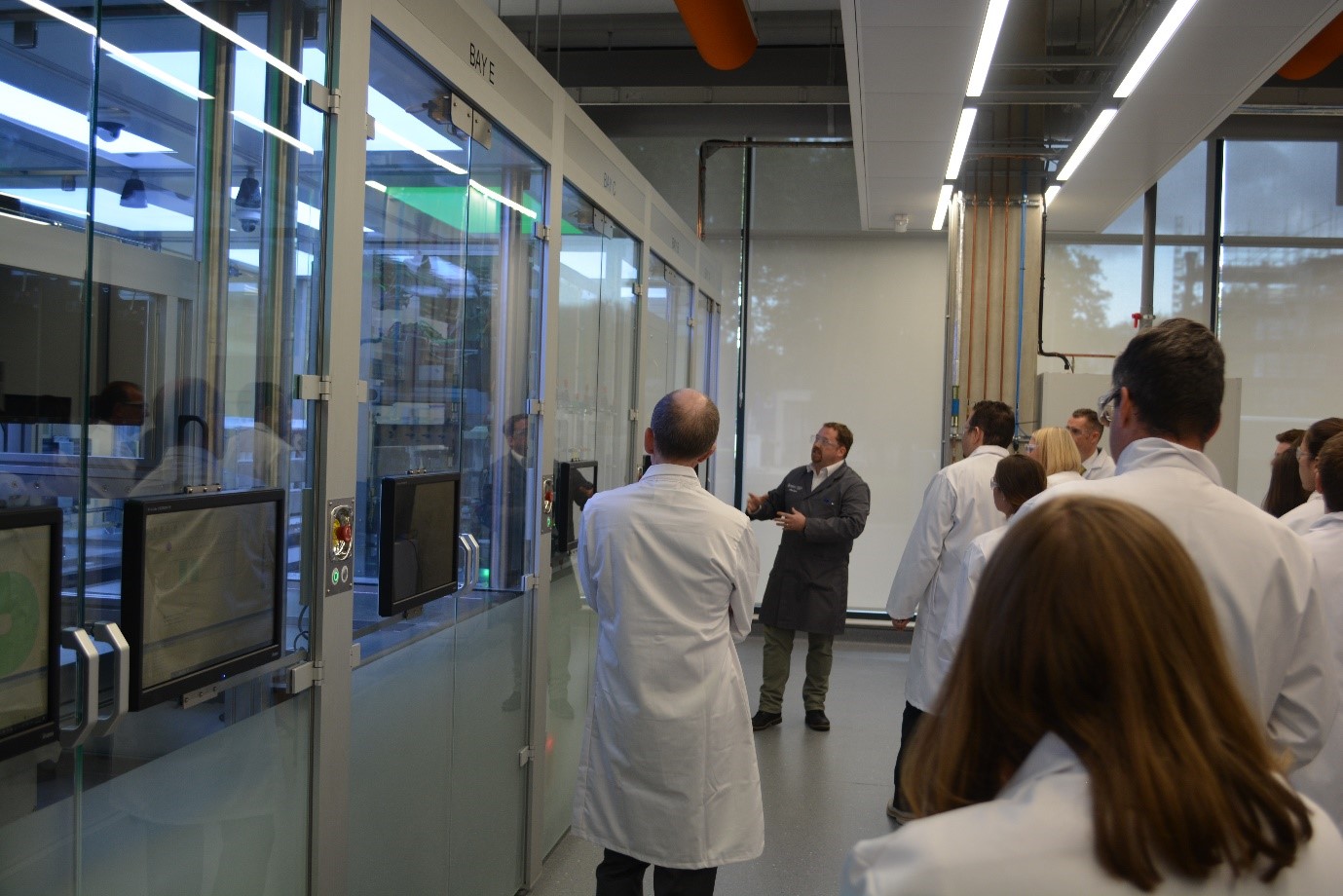

The Formulation Engine is a £3 million bespoke facility that allows users working in the Materials Innovation Factory to create an entirely automated workflow – formulating products, testing properties and analysing functionality.

The facility uses a unique modular approach, allowing up to six separate processing and testing stations to be connected together to create a seamless end to end process.

Dr Ben Slater, Business Development Manager for the Materials Innovation Factory, said “The Formulation Engine is a unique capability that provides unparalleled support to researchers in our materials chemistry community. Its high-throughput ability will transform the process of testing and formulation, whilst making it extremely affordable and accessible to industrial and academic researchers.”

Funded through the Sir Henry Royce Institute, the Formulation Engine launch took place as part of the annual Industry-Chemistry Engagement Meeting (I-Chem) which attracted more than 50 representatives from the research and business community.

The Formulation Engine was developed by UK robotics specialists, Labman Automation and is designed to future proof new formulation workflows. With the assistance of the MIF team, the modular approach will allow users to develop new testing stations which can then work seamlessly with other robot modules within the platform.

A collaboration between the University and Unilever, the Materials Innovation Factory is an £81 million facility dedicated to the research and development of advanced materials.

It houses an array of formulation and analytical equipment and is a founding partner of the Sir Henry Royce Institute, a national institute for materials science research and innovation.