Engineers at the University of Liverpool are part of a £10.6million innovative aerospace project that aims to develop a novel test and certification process for aeronautical structures, which will combine virtual and physical tests to provide a step reduction in development lead-time and costs.

The `Smarter Testing‘ project is led by Airbus UK and partners include the University, Dassault Systemes UK, Center for Modelling and Simulation (CFMS), National Physical Laboratory (NPL) and GOM UK.

The project partners also intend to build a ‘Centre of Excellence’ for Smarter Testing in the UK and hope to secure 98 jobs across the consortium in 2029-30.

Professor Eann Patterson and Dr Will Christian from the University’s School of Engineering are providing their expertise and know how in testing and validation methodologies to the `Smarter Testing’ project.

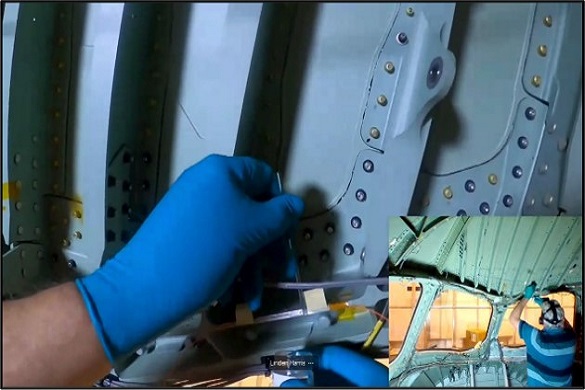

Their involvement draws on the H2020 MOTIVATE project which developed a step change in the testing process by enabling technologies demonstrated in laboratory conditions to be used in a structural test on an aircraft subcomponent. This improvement reduces costs, risks and time associated with product development.

It also utilises results from the DIMES project which developed an integrated measurement system for ‘on-line’ detecting and monitoring damage based on a diverse range of sensor systems. Coordinated by Professor Patterson, the findings of the DIMES project are published in three recent Royal Society Open Science papers.

Professor Eann Patterson FREng, AA Griffith Chair of Structural Materials & Mechanics, said: “This is an exciting and innovative project to be part of and I look forward to seeing the technologies in testing and validation that we have developed through our research programmes being used to improve manufacturing within the aerospace industry.”

Steve Raynes, Head of R&T Business Development, Airbus in the UK, said: “Smarter Testing will bring together the best of industry and academia, who will collaborate to revolutionise a range of test and certification processes. Our vision is a long-term one and we are confident the foundations we lay with this project will strengthen the UK’s reputation as trusted specialists in this vital field.”

Minister for Business Paul Scully said: “This multi-million-pound cash injection will safeguard vital jobs and support the aerospace sector as it builds back stronger after the pandemic. Manufacturing is at the very heart of UK industry, and innovative processes will ensure that the UK is at the forefront of global efforts as we develop technology that can power a green aviation revolution.”

The `Smarter Testing’ project is one of five innovative aerospace projects backed by nearly £90 million Government-industry investment set to revolutionize aerospace manufacturing in the UK.

Professor Patterson writes a weekly blog Realize Engineering which promotes public understanding of engineering.

Image below: Partners from the University, EMPA, Dantec Dynamics GmbH, Strain Solutions Ltd at EMPA (2019)